DYWIDAG

DYWIDAG Threadbar Anchors

DYWIDAG Threadbar Anchors are an actively tensioned ground anchor system and correspond to DIN 4125 and EN 1537 regulations. Due to the active tensioning, anticipated deformations of the system and deformations at the civil engineering measure are minimised or entirely eliminated. This applies both to temporary structures (e.g. temporary pit support systems) and permanent tie backs.

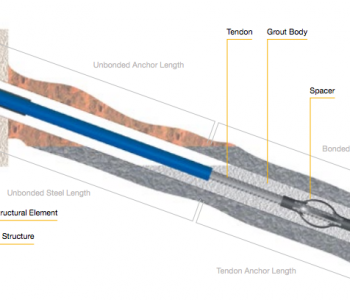

By definition, an anchor consists of three main components:

- Bonded length: The anchor is fixed in the borehole using grout (cement mortar) and can transfer the forces to the loadbearing soil via bond and skin friction

- Unbonded length: The bar is uncoupled from the borehole using a plain tube (sheathing) so that it can freely extend in the unbonded length. This way, tension can be applied to the anchor system

- Anchor head: The anchor head transfers the anchor force to the substructure and thus to the structure that needs to be anchored

Once the grout has sufficiently hardened, the load bearing capacity of each anchor is tested during an approval test. If required, anchors can be supplied retensioned or detensionable. Permanent control of anchor forces can be realised by installing load cells. Alternatively, permanent controls can also be carried out at the anchor head or in the borehole using the contactless force measuring system DYNA Force® that has been specially developed together with DYWIDAG.

Key features

- Threadbars with proven coarse GEWl® Thread that is suitable for on-site use along the entire length; lengths can be adjusted on site without any problems using the appropriate accessories and equipment

- Various steel grades

- Variable anchor head and angle compensation designs

- Easy handling: tensioning, retensioning or detensioning thanks to screwable anchorage

- Easy overhead installation – for instance in cavern roofs – due to the high rigidity of the bar system

- The DYWIDAG threaded bar system has an ACRS approval for both the GEWl® and WR bar

High tensile WR bar systems

DYWIDAG Prestressing Systems are world renowned for reliability and performance, most suitable for all applications in post-tensioned and prestressed constructions. They embrace the whole spectrum from bridge construction, buildings, to civil applications, above and underground.

Internal bar tendons are mainly used in concrete, composite and masonry structures. Internal unbonded and external bar tendons are used for concrete, composite, steel, timber and masonry structures. Typical applications are transversal prestressing, strengthening of bridges, rehabilitations, connection elements for steel structures and machines and temporary applications.

Post-tensioning Threadbar characteristics

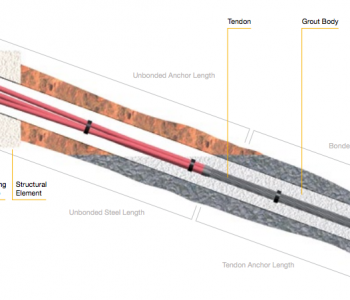

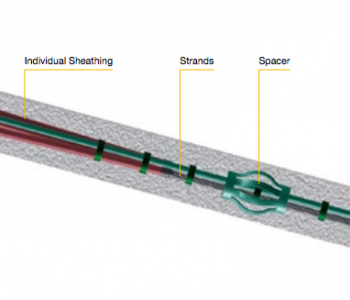

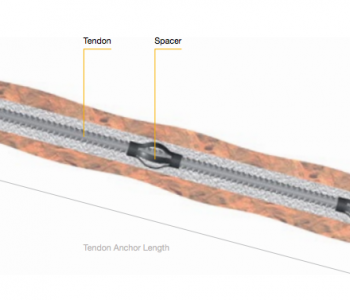

DYWIDAG Strand Anchors

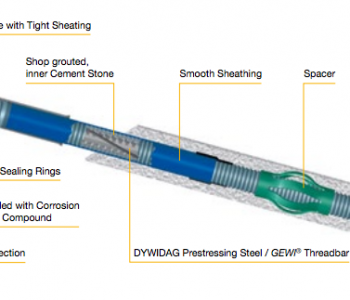

DYWIDAG Strand Anchors are an actively tensioned ground anchor system and correspond to DIN 4125 and EN 1537 specifications. Tensioning minimizes or eliminates anticipated deformations of the system and deformations at the civil engineering measure. This applies both to temporary structures (e.g. pit support systems) and permanent tie backs. The strand anchors are produced with double corrosion protection (DCP): each individual strand is covered by corrosion protection compound and inserted into an individual duct in the factory. As long as the grout used for anchoring is load-bearing, the anchor force is unlimited because the number of strands that can be combined in the anchorage is variable at will.

Removable strand anchors are available on request.

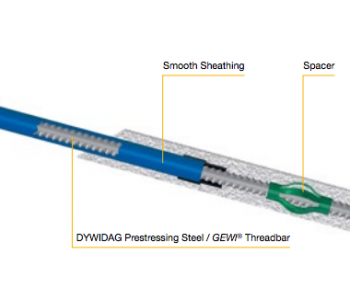

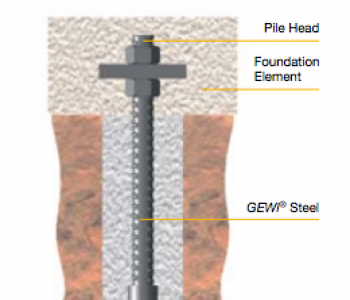

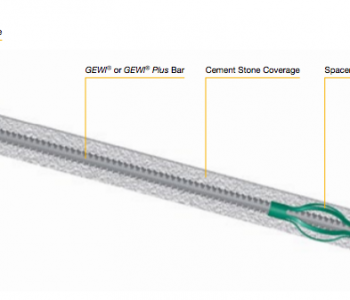

GEWl® Pile System

GEWl® and GEWl® Plus Piles are micropiles in accordance with DIN 4128 and EN 14199. Usually, they are not tensioned and act as a passive foundation system. A GEWl® Threadbar is inserted into a borehole with a maximum diameter of 300mm and centered using a spacer. Afterwards, the borehole is filled or pressure grouted with cement mortar from the bottom up. The grout simultaneously serves for transferring forces to the soil by skin friction and as standard corrosion protection (SCP). Like in solid construction, the alkaline environment of the surrounding cement stone coverage is used for protecting the reinforcing steel. If the cement stone cover does not offer sufficient protection in case of aggressive foundation soil or ground water, the GEWl® Pile is also available with double corrosion protection (DCP). The steel tendon is clad in a plastic corrugated sheathing and the annular space is grouted at the factory

DYWIDAG Soil Nails

DYWIDAG Soil Nailing is a passive system for stabilizing slopes and sidehill cuts or rock as well as for stabilizing construction pit walls if deformations are irrelevant. The load-bearing system significantly differs from ground anchors (actively tensioned) and tensile piles. In the case of soil nailing, the load-bearing capacity of the complete soil is increased because it is consolidated by the soil nails.

DYWI® Grip

The DYWIDAG glass fiber reinforced plastic fully threaded, Threadbar, is a compostie material composed of high performance resins and high strength glass fiber. It is supplemented with an array of various additives, which are then processed using very specific technology.

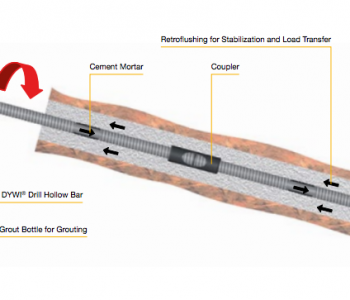

DYWI® Drill Hollow Bar System

The DYWI® Drill Hollow Bar System combines the geotechnical load-bearing system with the creation of a borehole. Thanks to the self-drilling hollow bar system with simultaneous grout flushing, the installation procedure can be decisively eased and shortened. The DYWI® Drill Hollow Bar serves as a drill rod. It is fitted with a lost drill bit at the top that can be adapted to different soil conditions. After each single section of 1 to 6m, the subsequent bar is coupled to the previously installed segment.

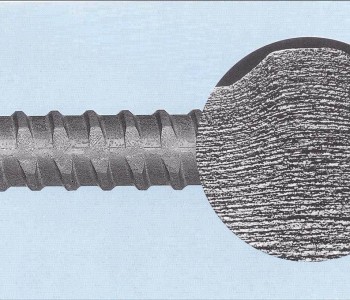

Thermal Diffusion Galvanizing (TDG) and Hot Dip Galvanizing (HDG) are the only two coatings available that are created by zinc diffusion. Zinc atoms diffuse into the steel substrate and combine with iron atoms to form a zinc / iron alloy layer on the steel surface.

With HDG, the diffusion time is about 2 minutes; depth of diffusion into the substrate is 1 micron, average iron content in the coating is about 2% and the average coating hardness of the alloy layers is about 250 Vickers. When an item is withdrawn from a molten HDG bath, pure zinc solidifies on top of the alloy layers and generally makes up half the coating thickness.

With TDG, the diffusion time is about 2 hours; depth of diffusion into the substrate is 10 micron, average iron content in the coating is about 18% and the average coating hardness is about 400 Vickers. TDG consists of alloy layers only; there is no pure zinc on the surface.

TDG will generally last 2 to 3 times longer than an equivalent coating thickness of HDG. Resin fusion epoxy coating as per standard ASTM 1055 can be applied over the TDG to provide a 100 year design life.

DYWIDAG Tie Rods

DYWIDAG Bar Systems are perfectly suitable for transferring tensile forces and can therefore be used as tie rods. Due to the continuous GEWl® Thread, the bars can be cut, anchored, and coupled at any point and be adjusted to on-site requirements. This makes the system completely independent of installation conditions on site as well as of existing deviations or alterations.

The GEWl® System – Connecting Reinforcement

GEWl® reinforcing steel is B500B steel in accordance with DIN 488 with HOT rolled-on thread forming a special left-hand coarse thread along the entire bar length. The GEWl® System serves for coupling and anchoring these threadbars and has proven itself countless times during the last decades as an excellent connecting reinforcement on challenging jobsites. This treadbar (coupling) system can meet the 0.1 mm slip criteria of EN 15835 norm.